Introduction to Shipyard Welding Careers

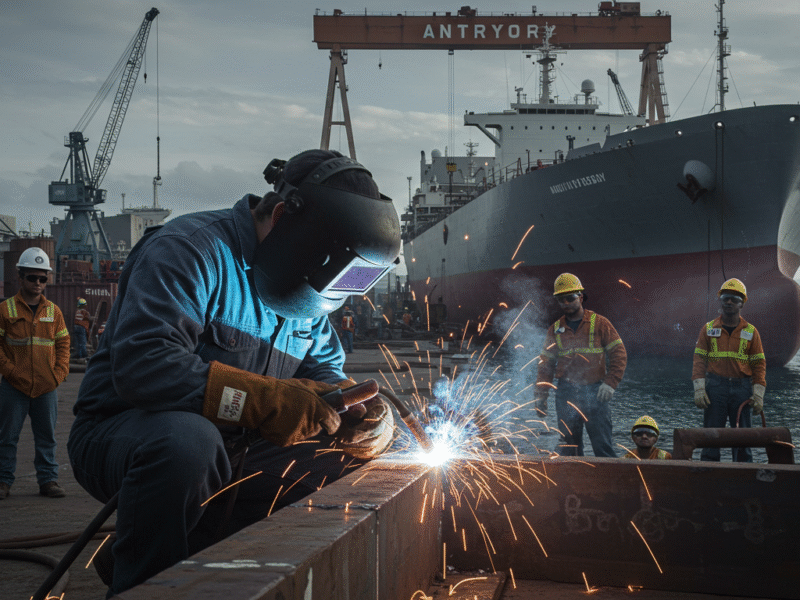

Imagine standing on the deck of a colossal ship you’ve helped build, feeling the salty breeze as it sets sail across vast oceans. This is the thrilling world of shipyard welding jobs in the USA, where skilled welders from around the globe transform metal into maritime masterpieces while securing a pathway to American dreams through visa sponsorship. If you’re a welder eyeing international horizons, the United States offers a booming maritime industry eager for talent like yours. This guide explores everything you need to know about landing these roles, from required skills to visa processes, salaries, and tips to make your application stand out.

What Shipyard Welding Jobs Entail

Core Responsibilities

Shipyard welders are the backbone of the maritime construction and repair industry. They work on diverse projects, including massive cargo vessels, naval ships, luxury yachts, and offshore platforms. Daily tasks may involve:

- Fusing steel plates on a ship’s hull

- Repairing pipelines on submarines

- Fabricating custom parts for cruise liners

Precision is critical, as even small mistakes can compromise a vessel’s safety, which may carry thousands of tons or hundreds of passengers.

Key Locations and Employers

Shipyards are scattered along U.S. coasts, particularly in bustling ports like Virginia, Louisiana, Washington, and Maine. Major employers include:

- Huntington Ingalls Industries: Operates in Newport News, Virginia, and Pascagoula, Mississippi, focusing on aircraft carriers and submarines.

- General Dynamics (Bath Iron Works): Based in Maine, specializing in destroyers.

- BAE Systems: Runs large facilities producing commercial tankers and naval ships.

- Bollinger Shipyards: Located in Louisiana, focusing on coast guard vessels.

- Eastern Shipbuilding Group: In Florida, builds fishing vessels and tugs.

Why Shipyard Welding Jobs Attract International Workers

High Demand and Industry Growth

The American shipbuilding industry is experiencing a resurgence due to increased defense spending, global trade demands, and renewable energy projects like offshore wind farms. A shortage of skilled tradespeople, including welders, creates opportunities for international talent. Employers often sponsor visas, signaling their need for expertise and willingness to handle immigration paperwork.

Pathway to Residency

Visa sponsorship can lead to temporary or permanent residency options, depending on the visa type, making these jobs a gateway to long-term opportunities in the USA.

Visa Options for Shipyard Welders

H-2B Visa: Temporary Non-Agricultural Workers

The H-2B visa is ideal for temporary shipyard projects, such as seasonal or peak-load needs. Key points include:

- Employers must prove a lack of U.S. workers and that the position is temporary.

- Welders qualify for roles like structural welding or pipe fitting.

- The process involves employer petitions to the U.S. Department of Labor and USCIS.

- Duration: Up to one year, with extensions possible up to three years.

EB-3 Visa: Pathway to Permanent Residency

The EB-3 visa targets skilled workers with at least two years of training or experience, including welders. Benefits include:

- Potential for a green card, allowing indefinite work and residency in the USA.

- Requires labor certification to confirm a shortage of qualified U.S. applicants.

- Common in high-demand areas like the Gulf Coast for long-term hires.

Other Visa Options

- H-1B Visa: Rare for welders unless combined with advanced engineering skills.

- TN Visa: Available for Mexican and Canadian citizens under NAFTA/USMCA for certain trade professions.

- Consult an Immigration Attorney: Always verify eligibility with a professional.

Essential Skills and Qualifications

Welding Techniques and Expertise

Employers seek proficiency in:

- MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick Welding

- Flux-Cored Arc Welding for thicker materials

- Working with metals like steel, aluminum, and exotic alloys

Additional Requirements

- Blueprint Reading: Interpreting complex diagrams for precise part fitting.

- Safety Knowledge: Familiarity with OSHA standards, confined space training, and handling hazardous materials.

- Physical Fitness: Ability to climb scaffolds, work in tight spaces, and lift heavy equipment in challenging environments.

- Certifications: American Welding Society (AWS) credentials like Certified Welder (CW) or Certified Welding Inspector (CWI). International equivalents may need U.S. validation.

Education and Experience

- Minimum: High school diploma or equivalent.

- Preferred: Vocational training or associate degree in welding technology.

- Experience: 2-5 years, with apprenticeships or on-the-job training highlighted for visa sponsorship.

Salary and Benefits

Competitive Pay

- Entry-Level Welders: $40,000-$50,000 annually.

- Experienced Welders: $60,000-$80,000 or more.

- Hourly Rates: $20-$35, with overtime opportunities during peak shifts.

- Top-Paying States: Alaska (premiums for harsh conditions) and Washington (Puget Sound Naval Shipyard).

Additional Benefits

- Health insurance, retirement plans, and paid time off.

- Relocation assistance in some cases.

- Unionized yards offer job security and negotiated wages.

How to Find Shipyard Welding Jobs with Visa Sponsorship

Job Search Strategies

- Online Job Boards: Use Indeed, ZipRecruiter, and LinkedIn with keywords like “H-2B welder jobs USA” or “EB-3 shipyard opportunities.”

- Company Websites: Check career pages of major shipyards like Newport News Shipbuilding or Bath Iron Works.

- Networking: Join welding forums, Reddit’s r/Welding, or professional groups on Facebook.

Application Tips

- Tailor Your Resume: Highlight relevant experience and certifications.

- Cover Letter: Explain your fit and willingness to relocate.

- English Proficiency: Demonstrate through tests like TOEFL if needed.

- Interview Preparation: Be ready for video calls discussing welding scenarios or safety protocols.

Challenges and Considerations

Visa Process Hurdles

- H-2B visas face annual caps, leading to delays.

- Competition is fierce; unique skills like underwater or robotic welding stand out.

Cultural and Practical Adjustments

- Adapt to American work culture emphasizing punctuality and teamwork.

- Plan for initial relocation costs, as sponsorship may not cover flights or housing.

Success Stories and Inspiration

Welders from countries like the Philippines and Nigeria have successfully landed H-2B roles in Gulf Coast or Virginia shipyards, some transitioning to green cards via EB-3. These stories highlight the potential for career growth and stability with persistence.

Daily Life as a Shipyard Welder

Typical Workday

- Start with safety briefings.

- Weld seams on hulls or repair pipelines in dry docks.

- Use tools like welding machines, grinders, and torches while wearing protective gear.

- Collaborate with fitters, electricians, and inspectors.

Work Environment

- Physically demanding with exposure to heat, humidity, or noise.

- Scenic breaks with waterfront views.

Career Advancement Opportunities

- On-Site Training: Learn advanced techniques or leadership skills.

- Career Paths: Move into welding supervisor, quality control specialist, or non-destructive testing roles.

- Visa to Citizenship: Temporary visas can lead to permanent residency and citizenship.

Family and Lifestyle Considerations

- H-2B Dependents: Spouses and children can join under H-4 (non-working status).

- EB-3 Dependents: Eligible for green cards from the start.

- Cost of Living: Higher in coastal cities like Norfolk or Seattle, but salaries adjust.

Tips for Success

- Build a LinkedIn profile showcasing projects.

- Secure endorsements from past employers.

- Practice English for interviews.

- Save for relocation costs.

Conclusion

Shipyard welding jobs in the USA with visa sponsorship offer a gateway to thrilling careers and new beginnings. With the right skills, determination, and strategic applications, you could soon be welding on American shores, contributing to maritime masterpieces.

Additional Resources